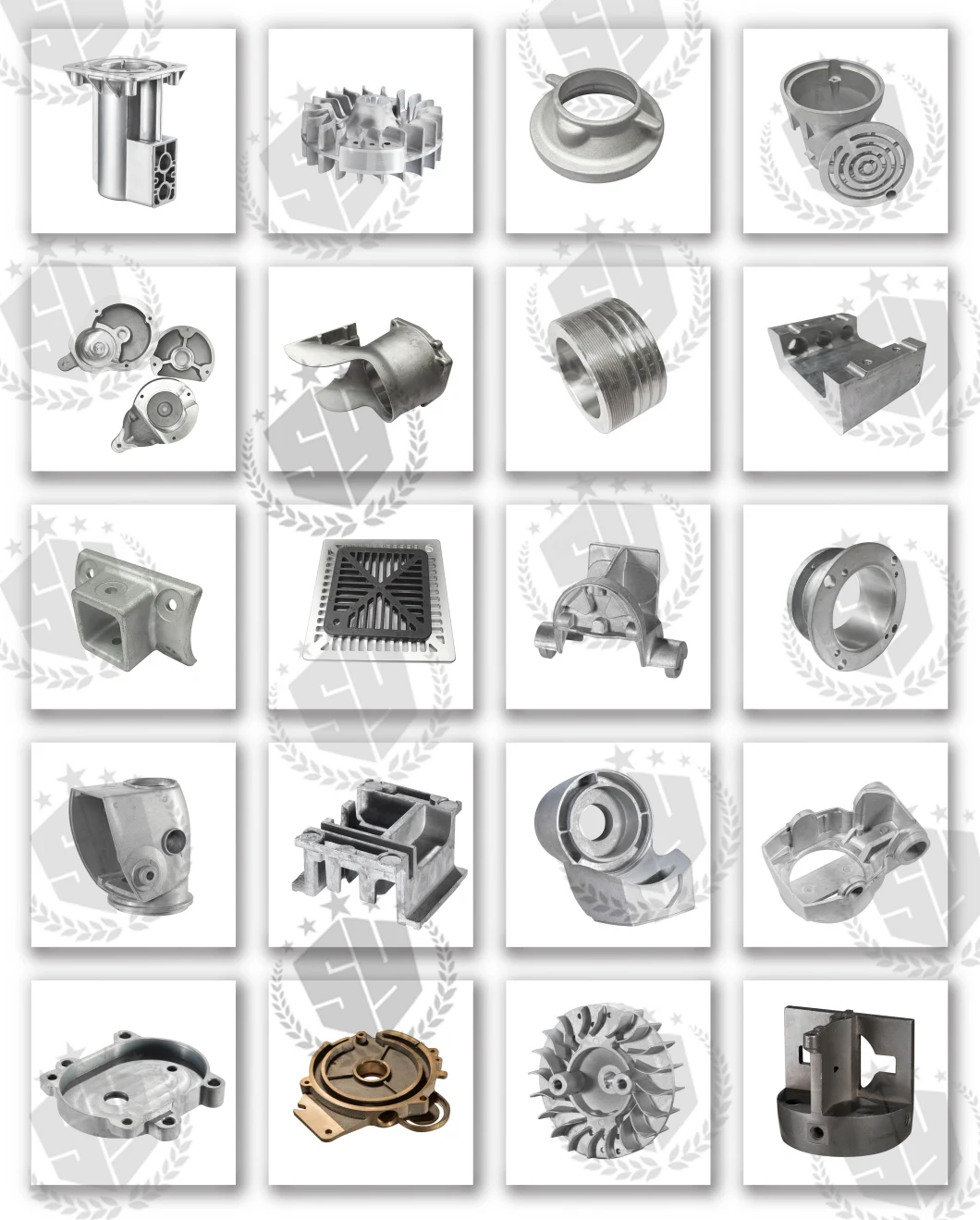

Custom Metal Brass Zinc Die Casting Mould Parts Anodizing Aluminum Die Casting

Qingdao Qiangsenyuan Technology Co., Ltd. is a processing manufacturer specializing in the customization of various non-

Description

Basic Info

| Model NO. | QSY |

| Pressure Chamber Structure | Horizontal |

| Tolerance Grade | 6 |

| Casting Surface Quality Level | 2 |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008, SGS |

| Tolerance | +/-0.01mm or as Your Requirements |

| QA | Optical Projector, Hardness Tester, CMM, etc. |

| Capacity | 500t/Month |

| Mould Life | 80000shots |

| Service | OEM/ODM |

| Transport Package | Plastic Film/Bubble Pack/Carton Box/Wooden Case |

| Specification | According to customer′s drawing requirements |

| Origin | Mainland, China |

| HS Code | 7616999000 |

| Production Capacity | 500t/Month |

Product Description

Specifications description

| Machining process | Die casting, CNC machining |

| Optional material | aluminum alloy, zinc alloy, copper alloy, tin-lead alloy, magnesium alloy, etc.Aluminium alloy: A356, A380, A383, A413, ADC12, LM2, LM25, ZL101, etc.Zinc alloy: ZAMK3, ZCDC1, Z33520, etc.Copper alloy: C83800, C84500, C83600, H59, H62, H63, T1, T2, T3, TU0, TU1, C54400, C51900, C52100, etc.Magnesium alloy:ZM1, ZM2, ZM3, ZM4, ZM5, ZM10, YM5, etc.All materials are with material certificates, in compliance with international material specifications and material substitution levels. |

| Optional surface treatment | Zinc plating, Chrome plating, Nickel plating, phosphating, blacking, painting, hand dull polishing, mirror polishing, elctro polishing, passivation treatment, etc. |

| Size | According to customers' drawings or samples |

| File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

| Application | Mechanical parts, telecom communication equipment, Auto & Motorcycle & Bicycle parts, Led light housing & Led Heatsink, Pump housing, Furniture accessories, new energy equipment, etc. |

Products cases

Manufacturing

Die castingCNC maching

We do hope to establish long-term cooperation with you. Should you have interest or any question, please contact us with no hesitate as below:

Prev: CNC Machinery Machined Machining Pointed-Tip Brass Parts Aluminum Die Casting

Next: High Precision Custom ABS Injection Molding Plastic Parts

Our Contact

Send now