Laser Cutting/Bending/Welding Sheet Metal Parts

Capability & Advantage:

Description

Basic Info

| Process | Separation Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.1mm |

| Customized | Customized |

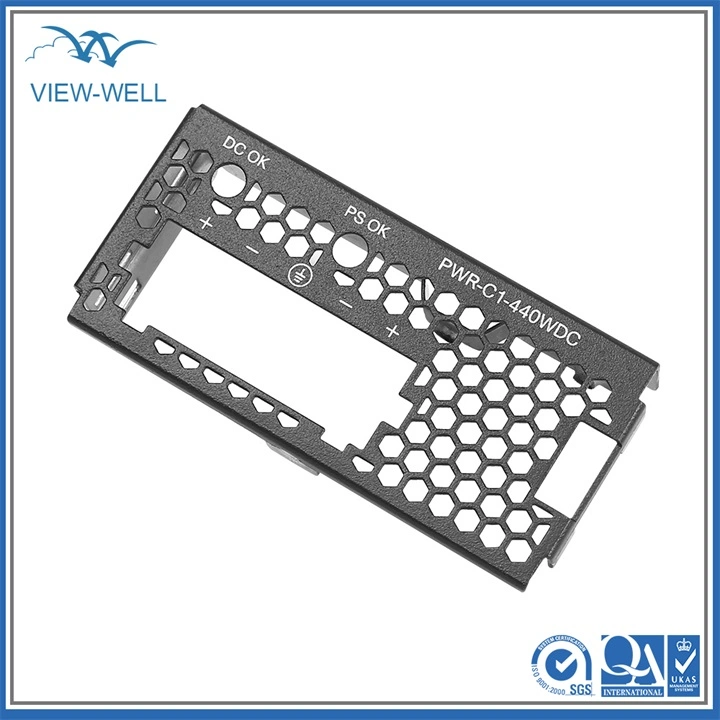

| Product Name | Metal Processing Stamping Parts 203 |

| Processing Method | Sheet Metal, Grinding, Welding, Assembly,etc |

| Materials Available | Stainless Steel, Carbon Steel, Brass, Bronze, Iron |

| Surface Treatment | Anodizing, Sandblast, Electroplating, Ect |

| Product Application | Aerospace/ Marine/ Metro/ Motorbike,etc |

| Processing Capacity | Material Thickness: 0.2mm-25mm |

| Processing Capacity 2 | Length: 1mm-3000mm |

| Materials Standard | GB, ASTM, En, DIN, JIS, BS, ANSI, SAE |

| Advantage | Strong Engineering Support |

| Certificates | RoHS, ISO9001:2008, SGS. |

| Transport Package | Carton and Wooden Case |

| Specification | Customized |

| Trademark | OEM |

| Origin | Shenzhen, China |

| Production Capacity | 100000 PCS/ Day |

Product Description

Capability & Advantage:

| Advantage | One-Stop Solution for Mechanical CustomersRich experience in Small Volume & Large varietyRich experience in Large Volume20+ years field experience, and 80+ engineers |

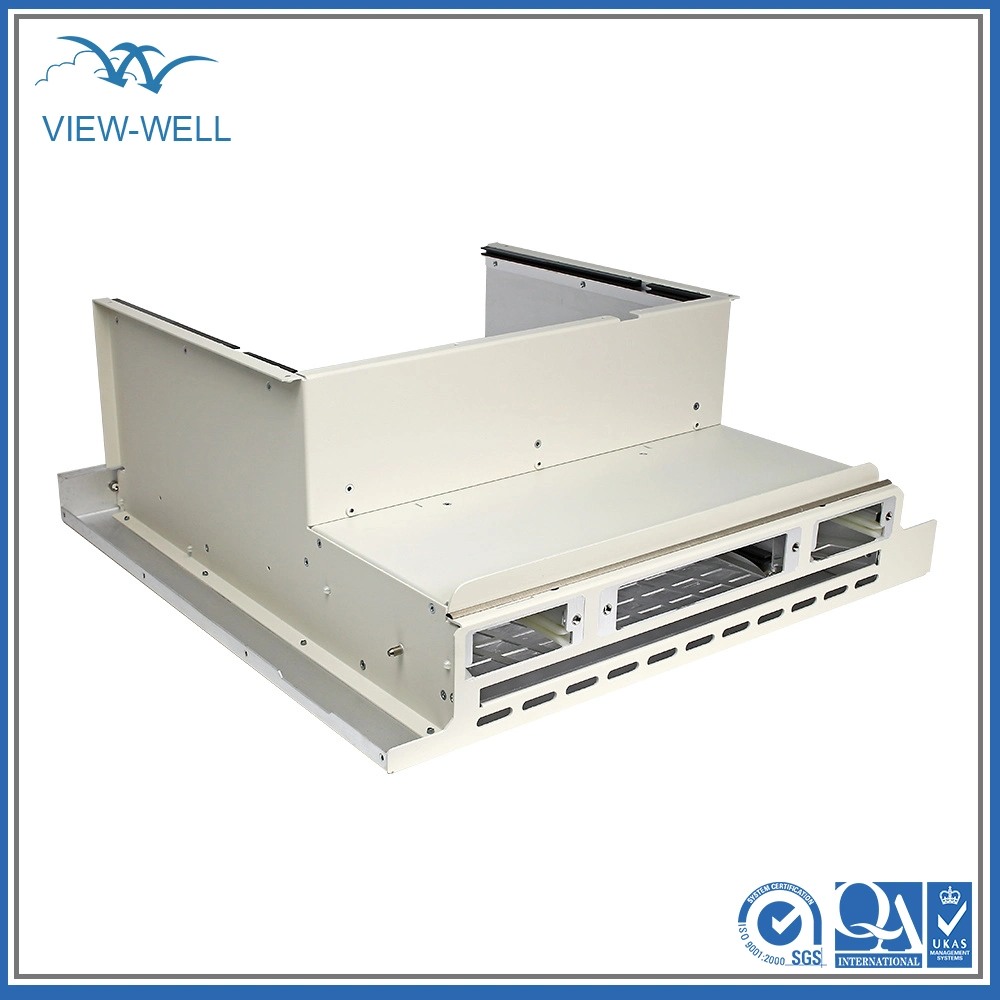

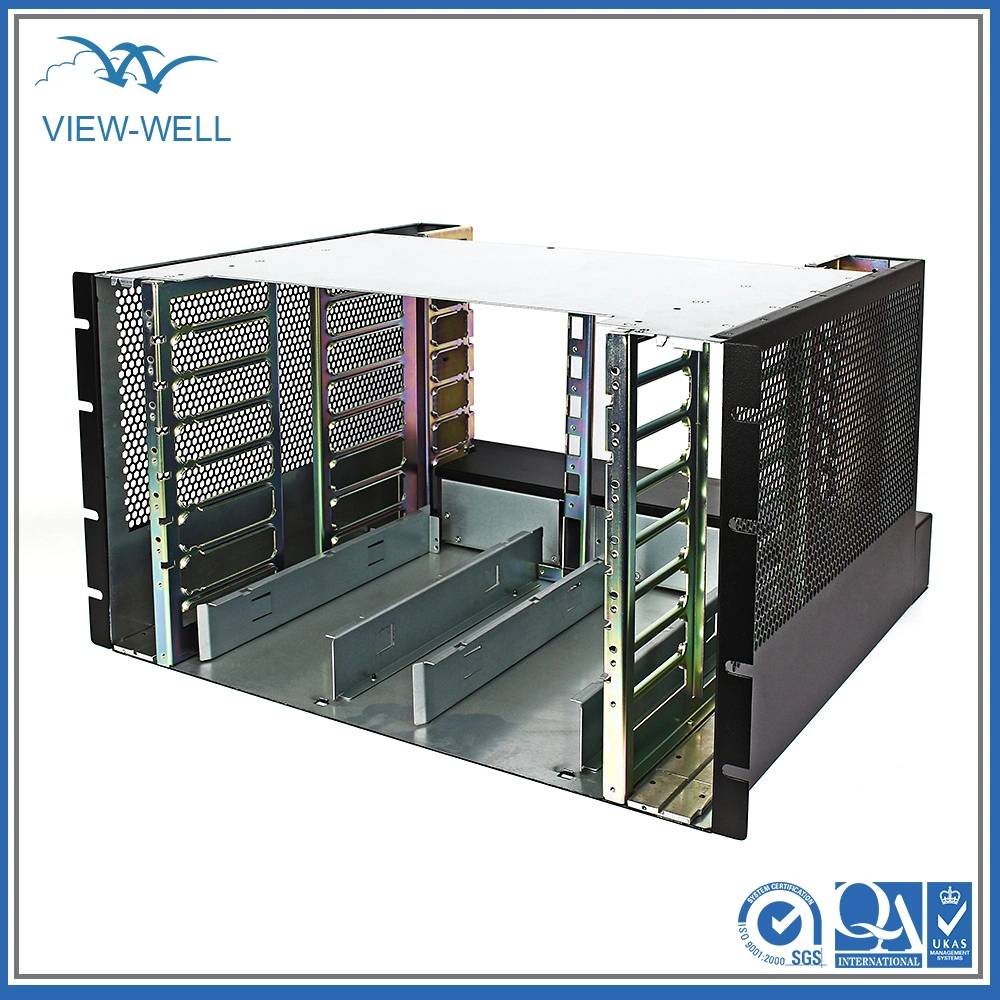

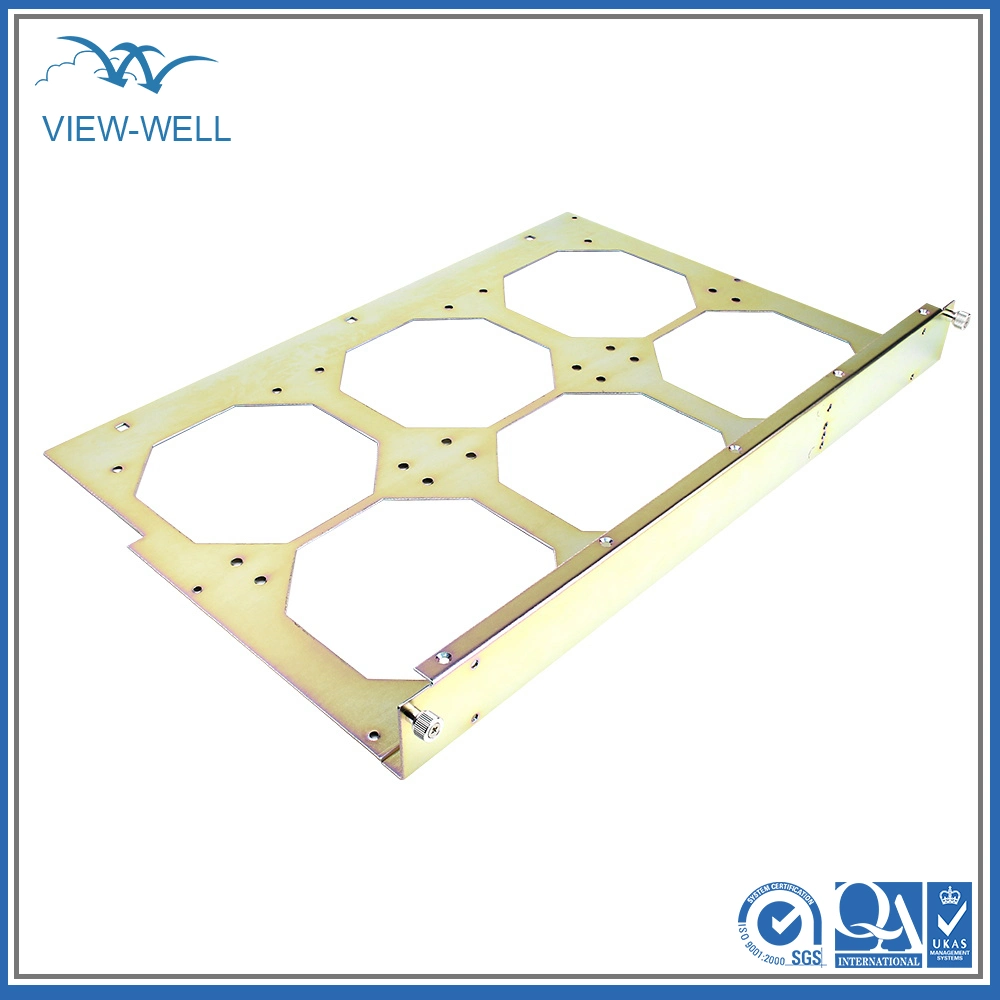

| Processing Method | Grinding, Welding, CNC machining, Turning, Milling, Stamping, Sheet metal, Assembly, Punching |

| Materials Available | Stainless steel, Carbon steel, Brass, Bronze, Iron, Aluminum alloy, Nylon, SPCC, SECC, etc. |

| Materials standard | GB, ASTM, EN, DIN, JIS, BS, ANSI, SAE |

| Processing Capacity | Material Thickness: 0.2mm-25mmLength: 1mm-3000mm |

| Tolerance | ±0.1mm |

| Surface Treatment | Anodizing, Sandblast, Electroplating, Powder coating, Liquid Painting, PVD, Electrolytic polishing, ect. |

| Equipment | 2 sets Amada Automatic Punching Machine, 4 sets Amada Bending Machine, 2 sets Amada Cutting machine,4 sets Riveting Machine, 50MAutomatic Powder Coating Line | |||||

| RFQ | Customer Inquiry →Engineering Communication →Cost Analysis →Sales Analysis →Quote to Customer» 1-3 Work Days Only» Submit RFQ with complete commercial terms | |||||

| Sample Making | Sample Order → Engineering Review → Sample Plan to Customer → Sample Status Tracking → Submit Samples with Doc.» Tooling L/T: 2-4 wks, Sample L/T: 2 wks» Continuous Sample Status Tracking» Complete Documents for sample approval | |||||

| Order Management | CRM System → Open Order Confirm → Logistic Arrangement.» Production L/T: 2-4 wks» Weekly Open Order Confirm» Preferred 3PL Service to Customers | |||||

| Quality Control | Certificates: RoHS, ISO9001:2008, SGS.IQC → IPQC → OQC/FQC → Quality Complain Feedback → Audit & Training.» Plant Audit and Qualified by world famous company» Strict Quality Management Procedure with Traceability | |||||

| Application | Aerospace/ Marine/ Metro/ Motorbike/ Automotive industries, Instruments & Meters, Office equipments, Home appliance, Medical equipments, Telecommunication, Electrical & Electronics, Fire detection system, etc. | |||||

Our Contact

Send now