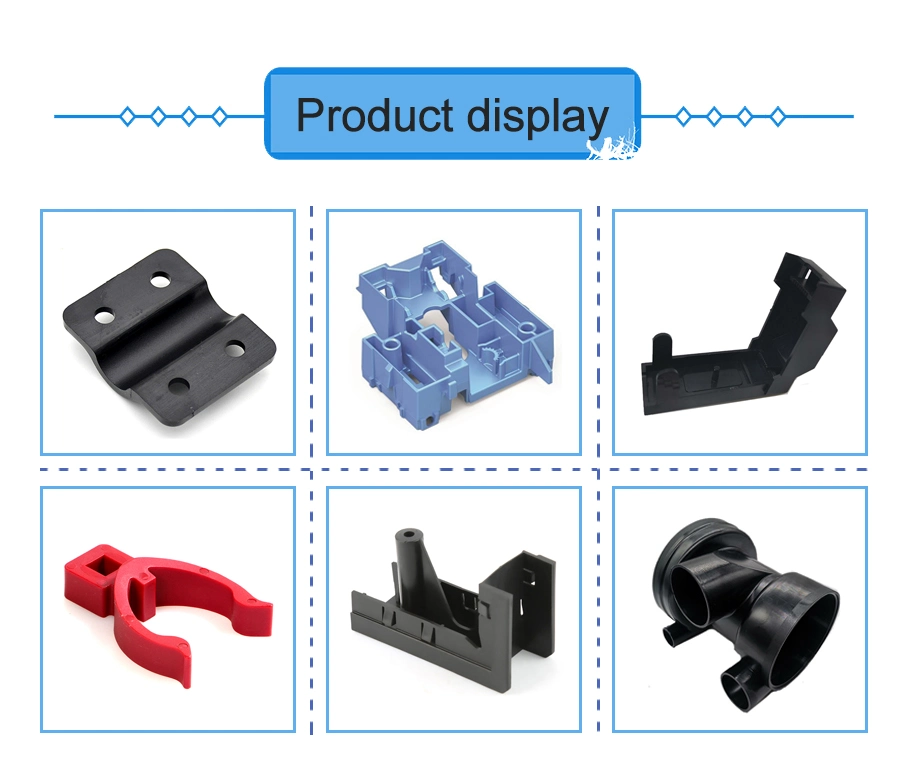

OEM/Customized PP/PC/PE/ABS/PVC/PS/POM/Nylon Plastic Injection Molding Parts

Description

Basic Info

| Model NO. | JF-052 |

| Item | Plastic Injection Junction Box |

| Technics | Plastic Injection |

| Part Type | Junction Box |

| Weight | According to Drawing |

| Export Markets | Global |

| Shipping Port | Qingdao, Tianjin, Shanghai, Ningbo |

| Packing | Wooden Cases or Export Carton |

| Place of Origin | China |

| Transport | by Sea or Air |

| OEM Service | Yes |

| Custom Made | Yes |

| Logo Printing | Customized |

| MOQ | 10-100PCS |

| Free Sample | Yes |

| Inner Package | Carton Box/Plastic Bag |

| Transport Package | Plywood Cases or Pallets |

| Specification | SGS |

| Trademark | OEM |

| Origin | Weifang City, Shandong Province, China |

| HS Code | 7326199000 |

| Production Capacity | 50000PCS/Month |

Packaging & Delivery

Package size per unit product 35.00cm * 25.00cm * 20.00cm Gross weight per unit product 20.000kgProduct Description

OEM/Customized PP/PC/PE/ABS/PVC/PS/POM/Nylon Plastic Injection Molding Parts

Our service:

We provide comprehensive turn-key solution based on our indutry clients needs whichincluding:product design,prototyping,mold making,mass production,assembly,packingand shipping service.

»Reliable service»Good production quality»Reasonable Pricing provided»Competitive shipping cost service»Small quantity order accepted»Professional engineering service when any modification required»Any assembly or customized package requirements are accepted

Processing program Our processing has a variety of processing, such as lathes, milling, grinding, boring, drilling, cutting, etc.,to provide you with a multi-faceted service.

| Item | Description |

| 1.Mould material | P20,718H,45#,STAVAX ESR S136,H13,2316,2083,2344 |

| 2.Hardness of steel | vacuum quenching ,nitride,HRC41-47, HRC46-50,HRC60 |

| 3.Inserts / Slider steel | H13 (DIN.1.2344),tempered with HRC46-50 |

| 4.Mould spare parts | H13 (Din 1.2344),tempered with HRC40-45,nitrited with HRC60-62 |

| 5.Mould base | LKM,HASCO |

| 6.Mould cavity | Single / Multi |

| 7.Runner system | Hot / Cold |

| 8.CAD centre for data formats | IGES,X_T,STP & DWG,etc |

| 9.Plastic material | ABS,PC,PE,PP,PS. |

| 10.Mould life | 80000- more than 1000000 |

| 11.Delivery time | 4-8 weeks |

| 12.Terms of payment | T/T, Paypal, Western Union and so on |

Our Services

1.Product Design,Structural Optimization,Process Optimization. 2.Mold Making,Plastic Molding Parts,Casting Parts,Machining Part. 3.Manage Project,Control The Delivery and Quality of Products. 4.Arranging the Transportation,Customs Clearance and other Matters for You.

Product range | Producr design,mold design, mold making and produce plastic parts |

Processing Craft | Mold fabrication, Injection etc; |

Material | ABS,BMC, SMC, AS,PVC,Nylon(PA),PP,PC,PE,POM,PS,HDPE,TPE,TPU etc |

Surface finish | Polishing finish,Texture Finish,Glossy Finish,Electroplating,Painting,Slik print,Rubber Painting etc |

Color | RAL/PANTONE color |

Mold Standard | DME,LKM,FUTA,HASCO etc. |

Mould Base | as per customer's requirement |

Tolerance | 0.01~0.1mm |

File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

Quality Control | Quality Control |

Inspection | IQC, IPQC,FQC,QA |

Application | All kinds of plastic injection parts being used in a variety of industrial application |

Advantages: 1. Competitive price. 2. Strict quality control system. 3. Quick mold making and delivery. 4. Advanced equipment, and excellent R&D teams. 5. Professional technicians and rich experienced workers.Rapid toolingFast and cost-effective process to create aluminum or steel injection molds for quick turn injection molding. Ideal for rapid prototyping needs or validating product concepts for production.OvermoldingOvermolding is a unique injection molding process that combines two or more components together. It is the best practice for the plastic manufacturing of multi-color and multi-layers products.Insert moldingInsert molding is a custom injection molding process that encapsulates components in a plastic part. It is most commonly used for prototype injection molding designs with threads and holes.Liquid Silicone Rubber injection moldingLiquid silicone rubber (LSR) is a flexible prototype injection molding process that produces elastic, durable parts. Get custom prototypes and production parts from 15 days.

Quality First,Price Best,Service Foremost! We assure you of our best services at all times! If you are interested in any of our products, please send message to us through below approach!

Prev: Ds Machining, EDM Machining Process, Electrical Discharge Machining, Aluminum CNC Machining Parts

Our Contact