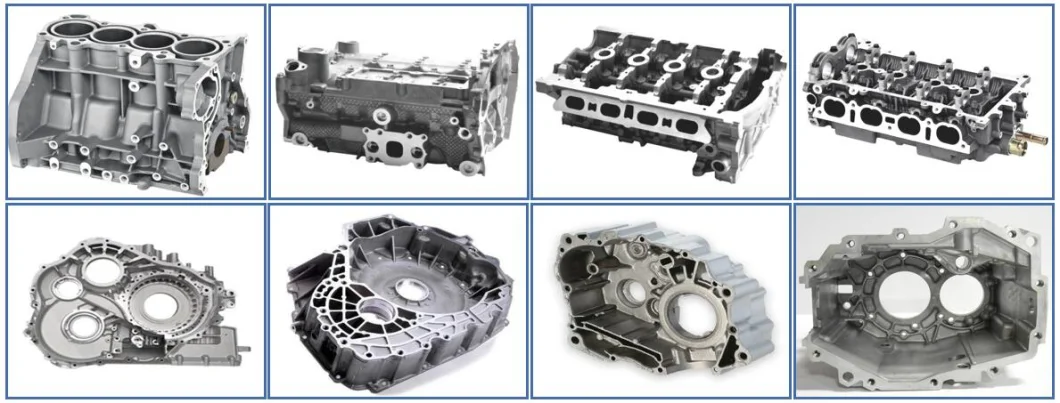

A380 Aluminum Alloy Die Casting Part Sand CAS Mold Cast and Low Pressure Castings

Relying on independent research and development,we have mastered four major processes such as gravity casting, low press

Description

Basic Info

| Model NO. | OEM |

| Pressure Chamber Structure | Vertical |

| Tolerance Grade | 6 |

| Casting Surface Quality Level | 2 |

| Certification | ISO 9001:2000 |

| Thickness | 1-200mm |

| NDT Inspection | Avaliable |

| Transport Package | Pallet |

| Specification | customized |

| Trademark | OEM |

| Origin | China |

| Production Capacity | 100000ton/Year |

Product Description

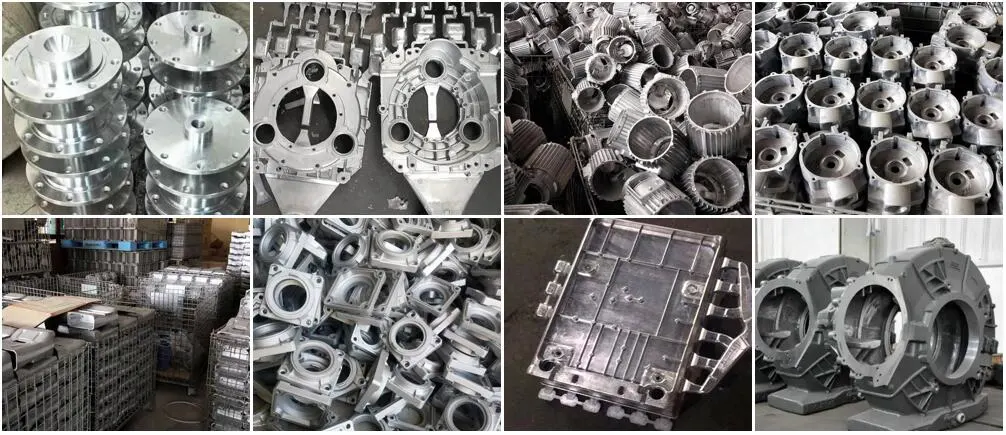

Relying on independent research and development,we have mastered four major processes such as gravity casting, low pressure casting, high pressure casting, sand casting and accumulated rich experiences of core technology experience in the research and development of key automotive aluminum parts. We have independent intellectual property rights of more than 100 items, and being as the leading company in China with new material research and development, 3D printing mold design Casting technology and mechanical processing as one of the professional production enterprisesWe can produce aluminum castings to meet the exact geometric specifications and details of your project. We will work with you at every stage of production, from design and casting to finishing and on-time delivery. Our engineers and technical staff will assist in solving your most complex casting challenges. We're here when you need us, at all hours, even on weekends.Low pressure and gravity casting production line:

low pressure casting machine group, robot gravity tilting and pouring machine group, centralized melting furnace, coated sand recycling line, complete set of equipment for aluminum scrap recycling, core making machine group, air/water quenching furnace and other heat treatment equipment, cleaning process machine group and other equipment.

High pressure die casting production line:

We have equipped with 3500T high pressure casting machine, 2000T high pressure casting machine, 1600T high pressure casting machine, 1250T high pressure casting machine, 1000T high pressure casting machine, 600T high pressure casting machine, 500T high pressure casting machine, 280T high pressure casting machine, etc.

There are more than 1,000 sets of high-speed, high-efficiency and precise five-axis machining centers, high-end horizontal CNC machining centers, fully automatic double-station high-speed CNC sawing machines, and vertical machining centers.

Industries served:Auto Parts Castings,Automotive Investment Casting,Aerospace & Aviation Investment Casting,Electrical Parts Casting,Firearms Investment Casting,Food Industry Castings,Hardware,Industrial,Rail/Train Industry,Tool Steel Casting

We specialize in custom rolling and forming of steel plate, custom metal and steel fabrication services, heavy steel plate fabrication, steel plate press brake forming, heavy alloy plate rolling, heavy duty plate bending, steel plate hot forming, steel plate cold forming, steel plate cutting, steel plate welding, steel plate heat treating and steel plate straightening services.

We have rich experience in manufacturing of large machined weldment or iron castings and forgings for industrial equipment like foring press, rolling mill, grinder, water conservancy and hydropower equipment, chemical equipment, mining machinery and equipment and all kinds of non-standard equipment with single weight up to 200 tons. Our products had been widely used in steel rolling, chemical, mining, hydropower, metallurgy and other industries.

Our companyl was founded in 1999, our factory currently has more than 1600 employees, covering an area of over 1,00,000 square meters, which has four sections: Equipment Assembly Dept., Metal Fabrication Dept, Precision CNC Machining Dept, Casting and Forging Dept.We provide full service fabricating service , from material supply, cutting and forming, rough machining, finish machining, welding assembly, and surface treatment, to the final packaging and transportation.

| Laser Cutting | Plasma Cutting | Flame Cutting | Water-jet Cutting | |

| Cutting Depth | 25mm | 100mm | 450mm | 250mm |

| Cutting Width | 3500mm | 4000mm | 6000mm | 3500mm |

| Cutting Length | 28000mm | 20000mm | 20000mm | 10000mm |

| Accuracy | ±0.2mm | ±1mm | ±0.8mm |

Our forming processing platform covers large bending machines, thick plate rolling equipment, transverse shearing and slitting equipment, and leveling machines. Our company offer a wide range of metal forming and bending services. From sinple aluminum channels or complex metal bending for large project, we can always meet your requirements. Our large press braking machine is with max 5000Ton in capacity, and we can bend the steel plate up to 15m in length.

| Bending | Press braking capability: | 2000Ton | Max Bending Length: | 75000mm | ||

| Plate Rolling | Max rolling width: | 3000mm | Max Rolling Thickness: | 150mm | ||

| Shearing | Thickness: | 0.4-33mm | Shearing Length: | 1000-4500mm | Anti-twist (W:T) | 5:1 |

| Leveling | width: | 100-2350mm | Thickness: | 1-40mm | Accuracy: | 0.5mm/1m |

We have a series of imported CNC Machining equipment, including large gantry machining center, horizontal boring and milling machine, turning and milling compound center, large vertical lathe machining center, heavy horizontal lathe machining center, dmulti-hole drilling and other machining equipment facilities.Our processing capabilities are as follows:

| Gantry Machining Center | Max Height:4000mm | Max Width:4500mm | Max Length: 12000mm | ||

| Large Boring Mill | X: 15000mm | Y:4000mm | Z+W:900+1000 mm | Max Weight: 250T | Bore Tool Dia: 280mm |

| Truning and Milling center | Height: 4500mm | Weight: 350T | Max Diameter:11000mm | ||

| Vertical Lathe | Height: 4000mm | Weight: 50T | Max Diameter: 5000mm | ||

| Horizontal Lathe | Max Length: 12m | Weight: 50T | |||

| Deep hole drilling | X:3000mm | Y:2500mm | Z:700mm | Hole Dia: 16-80mm | Depth: 700mm |

| Multi-hole drilling | X:7000mm | Y:3000mm | Z:700mm | Hole Dia:2-120mm | Depth: 320mm |

To ensure that the quality strictly meets the requirements, we have special quality inspectors to supervise and review the product quality for all projects, and we are equipped with a variety of inspection methods. For welding, we have magnetic particle inspection, X-ray inspection and other methods to inspect the weld quality. For precision machined products, we use advanced three-coordinate testing equipment to check product size, flatness, parallelism, concentricity, etc. For precision machined surfaces, we will also use special testing equipment to check that the surface roughness perfectly meets the acceptance criteria. Moreover, we will custom make inspection methods to serve for their project.

We have rich experience in manufacturing precision metal components in various industries, such as tube sheets, machine bed, power station energy storage finishing tanks, and even CNC parts for medical industry etc.

Industries we served: Construction machinery, printing and dyeing, food machinery, new energy environmental protection, nuclear power equipment, pressure vessel, etc...

We have established a sound quality management system, and has passed different kind of welding production certification, such as the following:

Our Contact

Send now